Guide to Adding K-Seal (Advanced Installation)

- If this is a vehicle you have recently purchased or are unsure of the maintenance history then it is advisable to perform a cooling system flush procedure before adding K-Seal.

- Make sure you shake the bottle thoroughly (at least 30 seconds) to ensure the contents are well mixed. Check the bottle after adding and if necessary add more water and shake again to ensure all contents are added to the system.

- When adding via the overflow/expansion tank, add K-Seal first and then top up the coolant. This helps to get K-Seal into the cooling system more quickly.

- It is fine to add K-Seal to a cold cooling system, just let the engine idle up to normal operating temperature. K-Seal can also be added to a hot system but use caution as the system will be under pressure and hot coolant can scald you.

If you add K-Seal directly to the radiator, ensure there is enough coolant to cover the core which (shelf at the top) to ensure that K-Seal is added to fluid rather than hitting the core first. One option is to pre-mix K-Seal in a larger container of water and then add to the radiator. This will assist the dispersal of the K-Seal throughout the cooling system.

Foaming is a rare side effect of adding K-Seal which will not interfere with the repair process. It sometimes occurs with head gasket issues. If you notice foaming, just idle the engine with the expansion or radiator cap off to let the foam escape. Once a repair is made you can drain and flush the system to remove any residual foam.

- For heater core repairs, set the heater controls in the ON/HOT position and confirm that hot air is blowing before adding

K- Seal. If there is no heat in the cabin, there is most likely an air-lock that will hinder K-Seal from circulating. The heater matrix is often the highest point of the cooling system, and any air in the system will gravitate there potentially impeding the flow of coolant. If there is no heat after adding K-Seal bleed the cooling system to remove any air locks.

- Once K-Seal has been added allow the vehicle to idle for about 20 – 30 minutes. Higher revs or driving the vehicle will increase pressures in the cooling system which can sometimes make a repair more difficult, in particular with head gasket issues (see additional instructions below).

- You may also wish to leave the cap off the expansion tank or radiator while idling to vent any air-locks and additionally prevent any vacuum developing as a result of from coolant still leaking.

- Occasionally with minor leaks, it may take multiple heat / cool cycles for K-Seal to be able to make a repair. Just use the vehicle as you would for up to ten days after and if K-Seal has not made a repair then it is, unfortunately, unlikely to do so.

- To help identify which particular part of the cooling system that might be leaking it is well worth having a look at our interactive diagram here: ENGINE COOLING SYSTEM INTERACTIVE DIAGRAM

- For motorcycles or other small cooling systems with only a couple of quarts/litres capacity, simply add a quarter to half of a regular bottle but make sure the contents are very well shaken first. If the leak remains then add the remainder of the contents.

K-Seal Installation Guide for Severe Over-Pressurising Systems (Head Gasket)

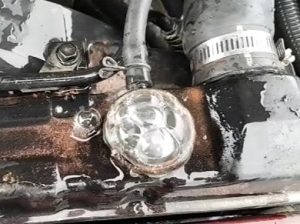

Coolant being expelled from the expansion or overflow tank while the engine is left idling. In this example, the cap is left off, but even in place, the system would build up the pressure and eventually force coolant out as well as raise the engine temperature as the coolant flow becomes restricted.

Coolant being expelled from the expansion or overflow tank while the engine is left idling. In this example, the cap is left off, but even in place, the system would build up the pressure and eventually force coolant out as well as raise the engine temperature as the coolant flow becomes restricted.

Bubbles that are visible in the expansion tank or top of the radiator are combustion gases from the engine getting into the cooling system.

In these instances, the extra pressure can actually prevent K-Seal from entering the cooling system or reaching the failure point. There are a few extra tips to help give K-Seal the best chance of making a repair.

• Adding K-Seal via the top hose of the radiator, or draining some coolant and mixing with K-Seal before adding back to the system, can help to get K-Seal into the cooling system more rapidly.

• If you can identify the problem cylinder then by disabling or removing the spark plug you will reduce the pressure blowing into the cooling system. This gives K-Seal more chance to reach and enter the failure point. Disabling the injector can also help, particularly in diesel engines where there is no spark plug.

• Another effective method is to idle the engine with the highest point bleed valve open which vents the combustion gases early and stops over-pressurising which has been demonstrated to then allow K-Seal to work. If possible, you can also add K-Seal while the front of the vehicle is elevated up to 45 degrees by parking on an incline. This allows any air in the system to rise and reach the expansion tank and escape.

Sometimes the failure is simply too large for K-Seal to make a repair. K-Seal is specifically engineered to seal holes up to 0.635mm / 0.025in in diameter and cracks up to 0.254mm / 0.01in wide by 12.7mm / 0.5in in length. As a rough guide, if you are adding coolant almost as fast as you are losing it, and the system is draining in around 15 minutes, then the leak is to severe for K-Seal to repair